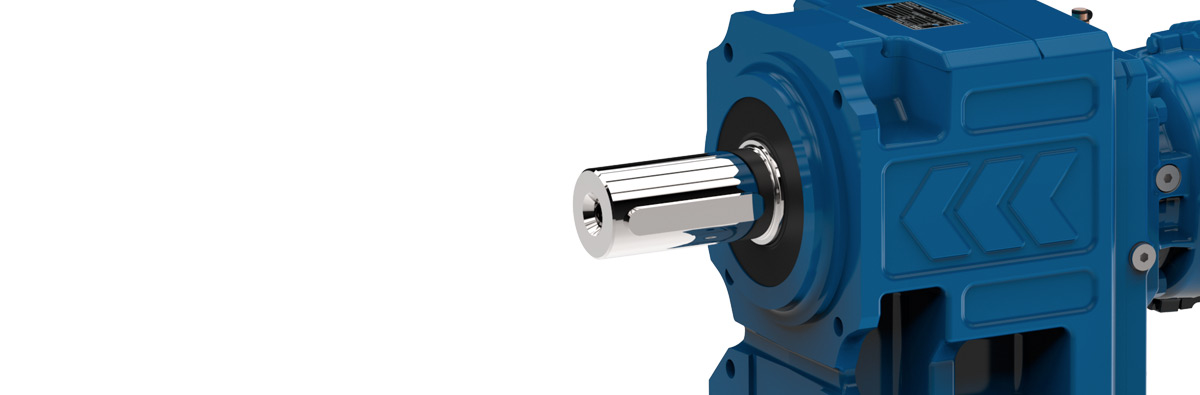

Wattdrive Geared Units Project

A leading manufacturer of plastic plant pots approached us with gearbox issues affecting their Rotary Plastic Moulding machine. They reported repeated failures of their two Renold U30 worm boxes, which led to production delays and higher maintenance costs. Additionally, they experienced excessive noise, vibration, leaking oil, and severe gear wear, complicating their operations. This is where Wattdrive geared units come in.

Since 1989, the company had regularly replaced these gearboxes, highlighting a persistent problem needing a long-term solution. Frequent failures disrupted production and increased downtime, causing operational inefficiencies.

To address these challenges, we recommended switching to more robust and efficient Wattdrive gearboxes. These are available from our stock in Burslem and include helical, helical bevel, and shaft-mounted options. The Wattdrive units offer higher torque output, enhancing the machine’s performance. They are also 20-30% more efficient than the existing units, leading to substantial energy savings. Additionally, the helical bevel gearboxes produce less noise and vibration, significantly improving the working environment. Their design features hardened and ground angled teeth, creating an efficient gear mesh that reduces wear and extends equipment lifespan.

Understanding the company’s desire to retain their existing DC motors, we proposed an IEC adaptor input flange for the new gearboxes. This solution allows immediate use of their DC motors while providing flexibility to install IEC AC motors with variable speed drives in the future, possibly as early as 2024. We stock IEC adaptors for frame sizes up to D160, ensuring compatibility with various motors.

Get in Touch Today Here